Konecranes adds more high-tech features to its heavy-duty overhead crane - SMARTON

Other News

Other News Subscribe to newsletter

Subscribe to newsletter

| 1 Jun 2015 |

Konecranes SMARTON® is a built-up, heavy-duty overhead crane for demanding processes, assembly, and maintenance use. SMARTON has a lifting capacity of up to 250 tons with a single trolley and up to 500 tons with two trolleys. The crane’s speed range is wide, and duty classes range from M3 to M8.

Konecranes has now further developed the SMARTON crane. The revamped crane is designed to make lifting operations as safe, smooth, and efficient as possible. The latest updates have been geared specifically towards improving the user interface for crane operators, customer service crews, and management.

User experience taken to the next level

The new SMARTON includes a tablet, which can be mounted to the radio controller or in the operator’s cabin. The tablet makes crane operation easier and more productive, as the operator receives crane- and process-related information directly to the tablet and is able to make adjustments to the crane. Optional camera views for safer and more effective load handling are also available.

Easy to Maintain

For maintenance purposes, the SMARTON tablet provides advanced troubleshooting and condition information of the crane controls. Maintenance personnel can access real-time information of the crane condition without the need to climb up to the crane service platform anymore, and wireless operation allows flexible use even during crane operation.

“The SMARTON includes Smart Features and TRUCONNECT® Remote Services, available to improve safety and productivity of the customer’s lifting processes,” says Tero Jaakkola, Product Manager. “SMARTON now makes it even easier to tailor solutions for customers who want to get the benefits of the latest technology and have safety and a Total Cost of Ownership approach as part of their ‘DNA’. With flagship products like SMARTON, we want to make sure customers who need advanced technology in their operations get it.”

Adaptable to different requirements and industries

Konecranes has sold SMARTON cranes since 2009 to 48 countries, including the Middle East. The main industries using the crane are paper, automotive, power, and steel, with other customers from general manufacturing and mining. As customer needs vary considerably from industry to industry, as well as from one location to another, there is a clear need for a product that adapts to these different requirements.

Modular and expandable

In its basic form, SMARTON comes with many standard features that will benefit the customer’s production process. Even if the load-handling requirements are more complex, SMARTON offers the option to further increase the intelligence of the crane with added Smart Features.

Smarter lifting starts here

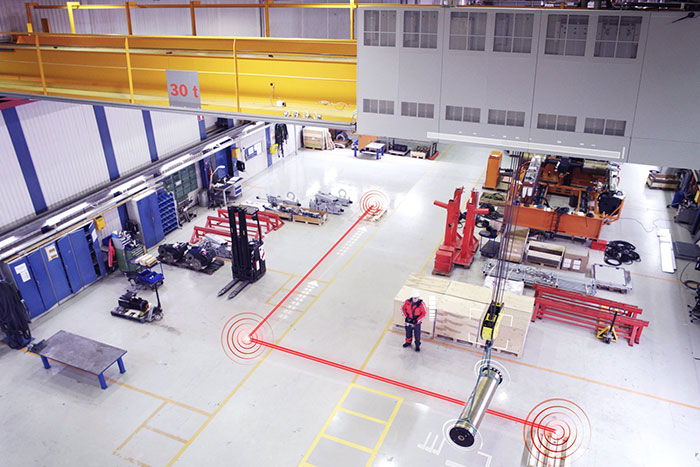

The use of the latest Smart Features, such as SNAG PREVENTION, HOOK CENTERING, and ACTIVE SWAY CONTROL, help improve speed, accuracy, and safety.

Latest Smart Features

- ACTIVE SWAY CONTROL limits load swing by controlling the bridge and trolley acceleration and deceleration. Sway Control allows faster load handling and more precise positioning. This feature also prevents damage to the load, crane, and surrounding area.

- HOOK CENTERING is designed to eliminate side pull during lifting by automatically positioning the bridge and trolley directly over the load. This feature means less wear and tear on your crane’s components, faster load cycle times, and ease of operation.

- SNAG PREVENTION is designed to stop all crane movement if the hook, sling or load accidentally gets caught on something. This safety function reduces the risk of hazardous situations while moving loads and helps to prevent damage to the load, crane, and surrounding area.