Siemens to Provide Kuwaiti Wastewater Treatment Plant with BioFlowsheet+ Solution.

Other News

Other News Subscribe to newsletter

Subscribe to newsletter

| 17 Nov 2007 |

Siemens Water Technologies will provide a high-performance nutrient removal system for the 180 mld (47.5 mgd) Kubd wastewater treatment plant (WWTP) located outside of Kuwait City, Kuwait. The solution, which is based on Siemens’ new biological process optimization program – BioFlowsheet+ Solutions, will help the WWTP meet required effluent levels. Siemens signed the contract for about US$7.4 million with Kuwaiti contractor Mushrif Trading and Contracting Company of Kuwait City. The plant will be commissioned in 2010.

Siemens’ proposed BioFlowsheet+ Solution was an alternative to the originally specified conventional MLE (Modified Ludzack Ettinger) process that consisted of an anaerobic selector, anoxic zone and fine-bubble aeration for nitrification, scraper clarification, and sand filtration/disc filtration. Compared to its conventional counterpart, Siemens’ solution will provide superior process design and performance, a smaller footprint, less energy consumption, and compact tertiary filtration.

BioFlowsheet+ Solutions is a new biological process optimization program from Siemens Water Technologies that integrates several key WWTP operations including biological, solids separation, solids treatment and controls to meet the needs of most wastewater treatment applications. The program evaluates effluent requirements, land availability and specific cost factors such as energy use, labor, and disposal.

The BioFlowsheet+ Solution for the Kubd plant will consist of four VertiCel systems (in two parallel operating trains), six 46m-high-performance clarifiers and eight Forty-X disc filters (with 24 discs apiece). The project marks the largest VertiCel system and Forty-X disc filter orders to date. Siemens will also provide an overall process warranty for the biological process to guarantee the plant meets required effluent quality levels.

Besides the merits of the design, Siemens presented as a reference a similar operating BioFlowsheet+ Solution in South Carolina, USA, which helped to convince the end user, Kuwait’s Ministry of Public Works that this was the right solution for the Kubd plant’s needs.

The VertiCel process is an activated sludge process that consists of reactors in series, with Vertical Loop Reactor tanks followed by fine-bubble reactor tanks. The process employs anoxic tanks, mixed and aerated with mechanical aerators, followed by fine-bubble reactors maintained in an aerobic state. Through optimized aerator selection and stratified dissolved oxygen levels, the VertiCel process requires less installed and operating power than conventional fine-bubble aeration processes.

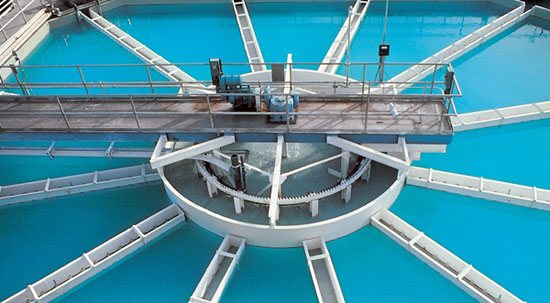

Siemens’ Envirex high-performance clarifiers use only six secondary clarifiers (as opposed to 10 conventional clarifiers), resulting in substantial savings in civil, piping and erection costs. Each clarifier combines the advantages of a Rim-Flo peripheral feed, peripheral takeoff clarifier with the Tow-Bro unitube sludge removal technology into a single high-performing activated sludge final clarifier. The Rim-Flo clarifier is designed for optimum hydraulic efficiency, resulting in a design that requires 50% less surface area than a conventional clarifier.

Similarly, the fully assembled, Forty-X disc filters will be delivered to the Kubd plant for installation in a small footprint concrete tank, compared to conventional sand filtration that would require a large gallery of piping, backwash pumps, and blowers. Forty-X and BioFlowsheet+ are trademarks of Siemens and/or its affiliates in some countries. VertiCel, Envirex, Rim-Flo and Tow-Bro are registered trademarks of Siemens and/or its affiliates in some countries.