Siemens shows efficient and smart solutions for water and sewage treatment

Other News

Other News Subscribe to newsletter

Subscribe to newsletter

| 11 Jan 2014 |

- Integrated engineering for more efficiency and better data quality

- Modular "smart water" solution for optimizing plants and water supply and sewage networks

- Economic operation of pump parks due to integrated drive systems

With the slogan "Making things right," Siemens is presenting intelligent automation and drive systems and industrial software for efficient water and sewage treatment at this year's IFAT from May 5 to 9, 2014 in Munich. The focus will be on integrated solutions supporting industry and municipalities with minimizing the consumption of resources and energy while maximizing security of supply. This includes integrated planning and engineering tools as well as seamless interaction of automation and drive components.

A further focus of the exhibition appearance will be "smart water" – intelligent solutions based on industry software. For this, Siemens will be showing the water management system SIWA, a modular software solution with which the operation of water supply networks can be optimized and drain systems and sewage flows can be intelligently controlled. Software modules are also used to detect leaks in water transport systems and water distribution networks and perform computer-aided simulation of complex pipe systems

Efficient water and sewage treatment starts at the planning stage. Siemens will be presenting an extensive planning tool called Consultant DVD at IFAT. It contains prepared text modules for invitations to bid, manuals, product information, and quick links. This gives plant planners effective support during all planning phases for plants in the water industry. Siemens will also be showing how, with integrated engineering, work processes can be efficiently parallelized, costs lowered, and resources saved. The COMOS engineering and data platform and the Simatic PCS7 process control system enable central data management for plant planners and operators throughout the planning and engineering phase right up to the operating phase. This permits efficient holistic plant management over the entire life cycle of an industrial plant so that time to market can be shortened, costs saved, and quality enhanced.

"Making things right" in the water and sewage industry also means smart management of plants as well as water supply and sewage networks. Siemens will present the modular water management system SIWA for pipelines, drinking water supply and sewage networks at IFAT. This "smart water" solution is based on the Simatic PCS 7 process control system and contains software modules that can be flexibly combined. Depending on operational requirements, these support the operator with optimizing plant operation, detecting and locating leaks, and performing highly dynamic simulation of pipe systems. Operation of water supply networks can be optimized using efficient schedules for pumps, tanks and waterworks. Complex interactions within the network can also be analyzed by computer-aided simulation of hydraulic behavior in the water supply system. For operators of sewage networks and sewage treatment plants, software modules are also provided that permit control of the sewage system and of the wastewater flows to even out the load on sewage treatment plants.

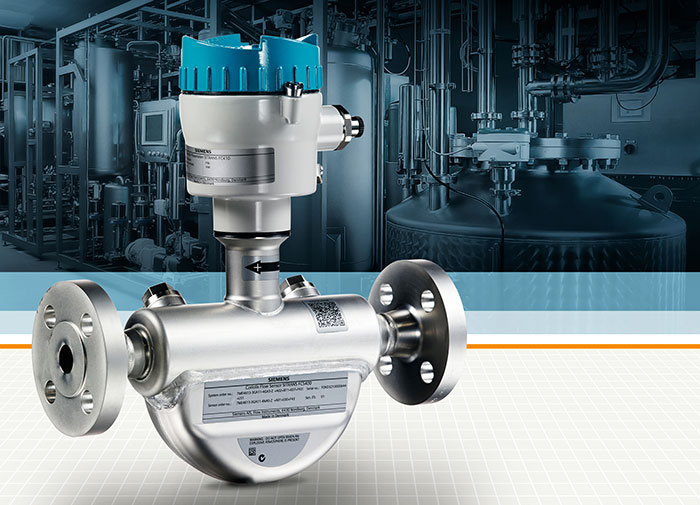

In addition to smart automation and software solutions, energy-efficient and reliable drive technology is also in demand for economic operation of water treatment plants. During the IFAT exhibition, Siemens will therefore be demonstrating the potential of "Integrated Drive Systems." For example, economic operation of pump parks can be achieved by combining the new Sinamics G120P Cabinet converter with Simotics motors. Due to optimum coordination of the components, the overall system achieves an efficiency of 98 percent. Integrated energy saving functions of the converter also contributes to high energy efficiency. Using application-specific functionalities, the drive speed can also be controlled as a function of process indicators, such as temperature, pressure, flow rate, and air quality, additional pumps can be switched on or off, and mechanical resonance and the resulting damage can be avoided in the pipe system.

Because plant outages in the water supply and sewage industry are extremely costly, at IFAT Siemens will also be showing solutions contributing to high availability. These include the modular Simocode pro S motor management system for low-voltage motors. It monitors all important power parameters and reliably switches off the connected motors in the event of overload or short circuits. This increases the process quality and lowers costs by reducing downtimes. Water plants frequently have a distributed structure with numerous remote stations. These can be connected to the central process visualization system using telecontrol, as Siemens will be showing at the fair with WinCC and PCS 7 - Telecontrol. Depending on plant operators' individual requirements, the system can be flexibly configured and enables inclusion of all information from the remote stations. This creates transparency and is a precondition for optimization of the entire plant, resulting in a clear reduction in costs for installation, commissioning, and maintenance.