The Green Precast System - a revolutionary, patented, highly efficient, low cost construction system.

Other News

Other News Subscribe to newsletter

Subscribe to newsletter

| 17 Feb 2010 |

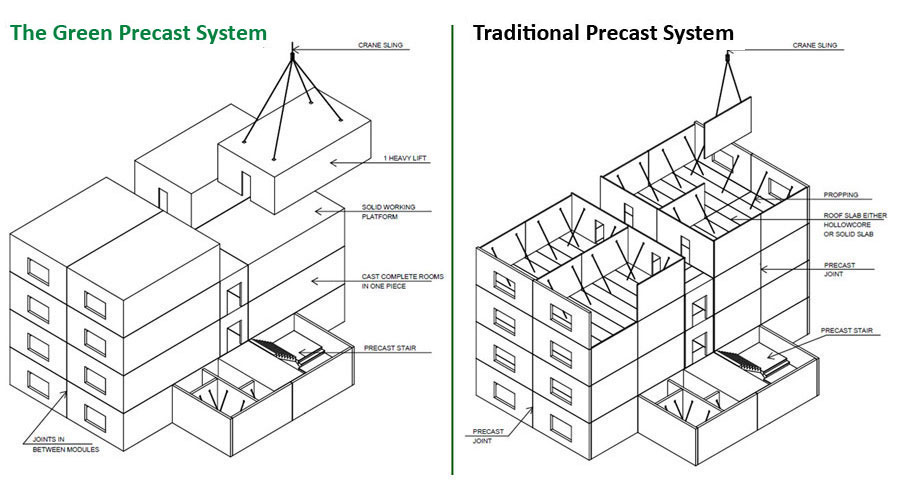

The Green Precast System is a revolutionary, patented, highly efficient, low cost construction system that produces a precast concrete building shell which integrates walls and ceiling to form individual 3D modules (rooms) that can be linked with any number of other modules to form more complex building structures, to a height of up to 10 storeys. The system provides immense design flexibility and can incorporate specified ceiling and wall openings, windows, doors, conduits, services and insulation moulded directly within each module.

The Green Precast System is ideal for repetitious building projects such as apartments, motels/ hotels, labour camps, housing units, age-care villas, student accommodation, site offices, industrial buildings and ski lodges – all built to the highest environmental specifications.

The Green Precast System provides developers a highly flexible building system that delivers strength, cost and time savings, durability, thermal and acoustic efficiencies and provides structurally superior resistance to natural disasters.

How it works

Durable concrete, reinforced with steel, super-plasticised with a low shrinkage rate is poured into a pre made mould (like a cake tin) and when set, contains the main components of a structure (ie walls & ceiling or walls & floor), resembling a large scale child’s ‘building block’ like a hollow 'Lego' piece. These building blocks can then be simply arranged and stacked as rooms to create a self supporting building structure, up to 10 storeys high.On larger scale projects the modules can be manufactured onsite and can be pre-fitted out with windows, doors, painting, electrical carpentry etc, prior to being delivered to the building site, providing a highly efficient system that helps expedite the construction process. So much so that The Green Precast System has achieved construction times up to 80% faster than conventional superstructure systems. From an environmental aspect this offers tremendous savings in energy and emissions minimising double handling and the need for haulage and longer term damages to roadways associated with the movement of heavy loads.

The Green Precast moulds can be manufactured to any practical size to suit the project’s needs and offer the most practical and cost effective build solution for the developer. For example for offsite manufacture where road transport is required, mould sizes may be restricted in size where as in larger projects where onsite manufacturing offers greater efficiencies, larger moulds can be manufactured.

The Green Precast Manufacturing System provides a proven, highly efficient all weather manufacturing facility that can be effectively relocated at the end of each project.

The Green Precast System provides developers a highly flexible building system that delivers strength, cost and time savings, durability, thermal and acoustic efficiencies and provides structurally superior resistance to natural disasters.

Flexible Design

The Green Precast System provides architects and developers endless design options with wall openings windows, doors and stairwells that can be pre-moulded into each module. Once onsite, the Green Precast modules are assembled according to the plans and the rest of the structure is added (roofing, veranda/s, floors, plumbing and finishing touches such as light fittings, final painting, tiles, carpet etc).Delivery is achieved by placing the module on a semi-trailer which is then transported to the building site, or more energy efficient onsite manufacturing situations may be craned to site, where the foundation has been constructed. The module is then manoeuvred into position by a crane. Once all modules are placed, the final part of the construction is then completed.

Structural Properties

This Patented System uses a hydraulically operated mould which is fully automated and operated so that it can be used many times over. It re-sets itself for daily use to within 2mm accuracy every time. It has been designed to be ‘foolproof’ so that the harshest site conditions will still enable a module to be poured on a daily cycle.Penetrations and Openings can be cast into the module or cut out later. The roof slab can also be moulded for stair openings, skylights, service ducts, lifts and the like. The Green Precast modules have even been inverted to provide a concrete base which can be utilised for a range of applications including usage as underground water tanks.

Module sizes can be made to order to suit your unique building and design requirements.

Collapsible Mould System

As concrete sets, it shrinks, like a cake in a tin. For this reason, it is very difficult to pour against a fully internal mould surface as the mould would have to be dismantled or destroyed to extract the unit.Green Precast Manufacturing System’s unique, patented mould collapses internally to facilitate the removal of the module and allows the mould system to be used over and over again for repeated production. The mould is fully automated and hydraulically driven with fine tolerances to ensure accurate repetitious casting on a daily basis.