Enventus 'Double Wheel Concept' improving energy recovery in AHU - download seminar presentation.

Other News

Other News Subscribe to newsletter

Subscribe to newsletter

| 8 May 2010 |

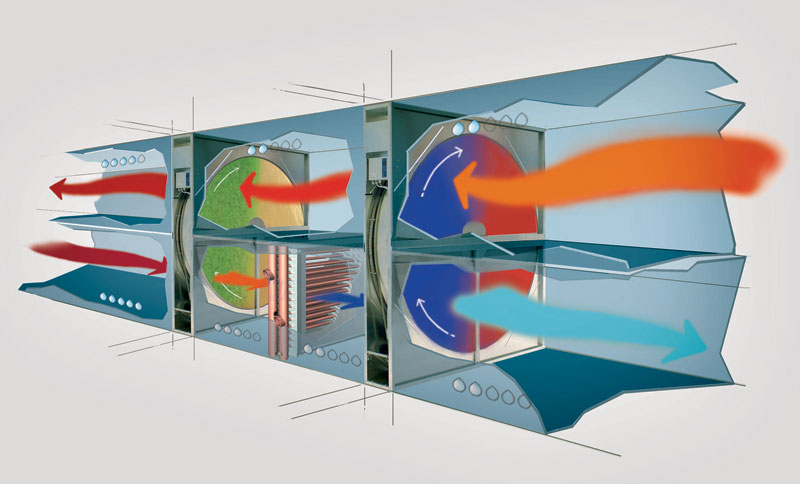

In regions with high humidity or buildings with dry cooling systems (chilled beams, chilled ceilings), the supply air needs to be dried. Traditionally air drying has been done by cooling the air to condense the humidity from the air and reheating it to requested inlet temperature.

Sorption rotors (sensible + latent heat) are providing an excellent method to precool and dehumidify the fresh air before entering cooling coil. The savings of cooling capacity due to sorption rotors is up to 50% of the cooling need of an AHU. After the sorption wheel, the supply air is passing cooling coil and is cooled down to dew point of requested supply air conditions. Usually, a reheating is requested to obtain right air temperature. This can be done with:- Water heating coil - expensive due to piping and regulation

- Electric heater - very expensive running costs

- Heat pipe system combined with reheating coil or electric heating element - expensive running costs with electric heating element or most effecitvely

- Non hydroscopic (sensible) wheel - double wheel concept!

Summary of the Enventus Double Wheel Concept

- Lower cooling capacity needed

- No additional reheating capacity needed

- Sensible wheel precools exhaust air - sorption rotor works even more efficient

- Good control of the supply air temperature

- Most energy effective solution for cooling and drying supply air in AHU units